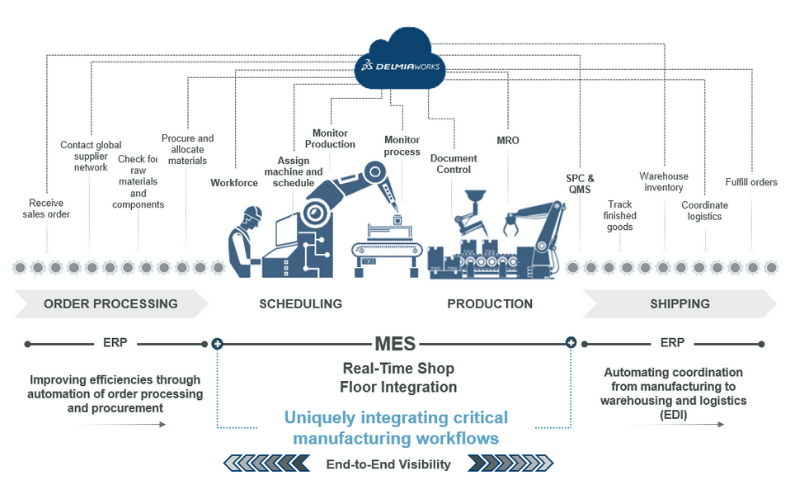

Book your DELMIAWorks Demo to learn how we can help solve your manufacturing challenges

Book a demo with one of our manufacturing experts to learn why DELMIAWorks is the right software to help you increase efficiency, reduce costs, improve scheduling and provide powerful data that helps you make informed business decisions.