Drive revenue growth with an ERP system designed for the manufacturing environment

Data, insights and intelligence are at the centre of manufacturing operations. By increasing the accuracy, speed and scale of those data insights, manufacturers can quickly understand and take action on competitive insights, enabling them to become competitively smarter and stronger.

Getting every department, team, and employee the right data at the right time is essential.

Quickly acting on that data can mean the difference between meeting a customers’ delivery schedules and quality standards.

Adopting a manufacturing ERP can also drive productivity. Increase the number of people and teams actively using an ERP system, so that they can all rely on a common source of information.

Manufacturing businesses are complex by nature. They rely on extensive coordination to maintain synchronicity across every stage of the production process. You can see an improvement in everything from daily productivity to translating shop floor data into financial insights when an ERP system is adopted across the organisation.

Advice on 10 ways to drive manufacturing ERP adoption

This whitepaper eBook from our partner DELMIAWORKS (formerly IQMS) gives you ten strategies you can implement to drive the adoption of a manufacturing ERP system across the organisation.

By increasing the number of teams using an ERP system, you can give people a sense of ownership and accomplishment. Each person and team within your organisation can see the progress they are making towards goals, and understand how they are making a real impact, when they have access to an ERP system. T

he wide adoption of an ERP system gives teams the opportunity to get real-time feedback on their progress – and of course – correct if needed.

We take your Privacy very seriously. Learn more about our Privacy Policy.

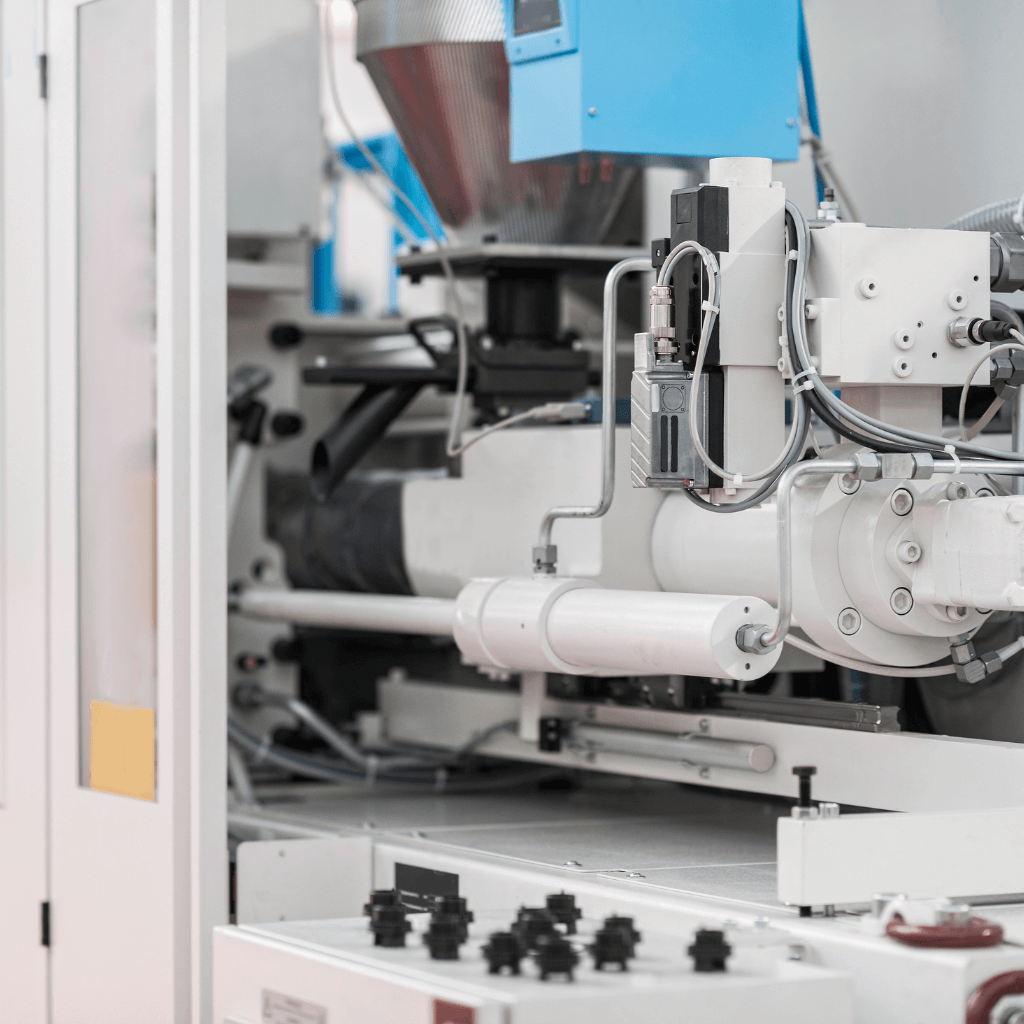

DELMIAWORKS manufacturing ERP system

DELMIAWORKS (formerly IQMS) provides mid-market discrete and process manufacturers with an end-to-end ERP (Enterprise Resource Planning) System and real-time production monitoring solution, to improve the efficiency and productivity of your manufacturing business.

Posted by Joe on 8th October 2020.