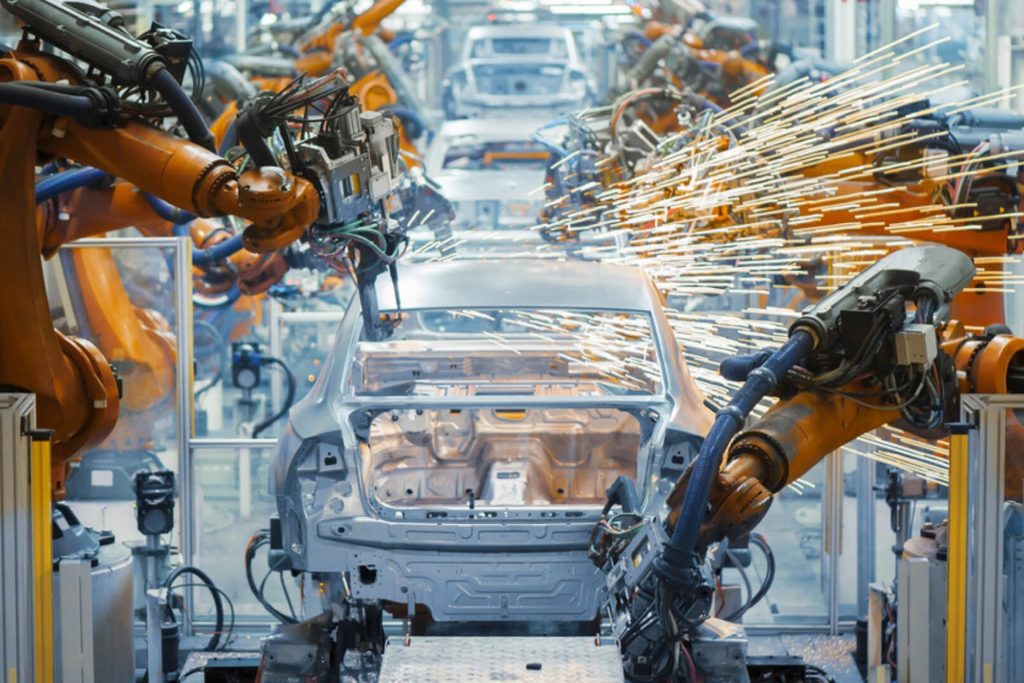

In a day and age where software has become so complex that it can now control the lights in your home just by hearing your voice, it makes complete sense that a manufacturing business would want access to software that understands and manages its entire manufacturing process and operations – plus has the ability to provide the right information, exactly when it’s needed. Here, we’ll detail exactly what the DELMIAWORKS Manufacturing ERP software does and the benefits it brings, to help you decide whether it’s the right software to help you improve the productivity and efficiency of your business.

Why use a Manufacturing ERP?

An ERP (Enterprise Resource Planning) system is a management platform that allows your business processes to remain connected through one single system.

For manufacturing companies, it’s particularly important to connect the processes for procurement, manufacturing, supply chain, sales and finance.

Some of the problems we regularly hear from our customers are that they’re struggling to access information at various stages of the manufacturing process, or that they’ve got a number of different systems trying to talk to each other with information saved in a number of different locations.

For others, they’re having meetings to try and gather information that should be readily accessible to them exactly when they need it.

“If you’re constantly in situations where you’re having meetings or video calls to find out information, then DELMIAWORKS will fix that. We believe that instead, you should be having meetings to make decisions because you already have all the information right at your fingertips.”

– Nick Jackson, Proximity.

This is the point where we would step in to help them to understand that by using the ERP system that works for them, they can greatly increase accountability and boost the productivity and efficiency of their business.

By implementing DELMIAWORKS, all of these issues essentially go away overnight.

Which ERP is best for manufacturing?

The problem with many ERP systems is that they’re often built with a specific process in mind and then using integrations, or by tweaking the system, they’re configured to work in a way to suit the manufacturing industry.

That’s where DELMIAWORKS is unique.

It has been built by manufacturers, for manufacturers.

DELMIAWORKS (fomerly IQMS) was built from the ground up by Randy Flamm, a Technical Service worker at GE Plastics who had a belief that the scheduling process in manufacturing could be made much more efficient.

Inspired by this belief, Randy developed a system with a ‘shop floor first’ philosophy, which provides an end-to-end manufacturing ERP System and real-time production monitoring solution to help you increase your manufacturing efficiency and gain visibility into the performance of your plant floor.

“To be a leader you have to work hard, without a doubt. But to be a leader over time, you have to work smart. That combination of DELMIAWORKS and SOLIDWORKS helps us to work smart.”

The platform has experienced widespread success in the automotive, medical, plastics and general manufacturing industries.

The ability to drill down extensively into data makes it an incredibly useful system for businesses operating in highly regulated industries, such as the manufacture of medical devices, aerospace or automotive where regulations such as ISO and FDA compliance, quality and enterprise-wide traceability are crucial.

Benefits of using DELMIAWORKS

Built by manufacturers, for manufacturers

This is not a system that has been built and then configured to work for the manufacturing industry. It’s been built from the ground up, by manufacturers, for manufacturers, so it understands the entire manufacturing process and what information you’ll require at every stage.

All your processes and data held in a single platform

From Bills of Materials (BOMs), raw material requirements and purchasing, right through to sales and finance. All your data is held in a single system, making everything and everyone accountable at every stage of your business processes.

Live dashboards with real-time analytics information

Having all your processes and data held in a single system gives you the ability to set up live dashboards, showing you information in real-time. Dashboards make it incredibly easy to digest large quantities of data, quickly. Whether you need to know information about a job from three weeks ago, last year, or even one that’s happening right now, the data is available right at your fingertips.

Objective data to inform your business decisions

DELMIAWORKS gives you the ability to drill down into your manufacturing processes, giving you visibility of any stages which may be more or less profitable than others. This gives you a wealth of data making it very easy when it comes to making informed decisions for your business.

If DELMIAWORKS would be the perfect fit for you, then find out how Proximity can help implement it for your business.

FIND OUT NOW >

Or if you’d like to learn more about DELMIAWORKS and how it can help make your manufacturing operations more efficient, you can find out more information here.

Posted by Rob on 11th February 2021.