Although family tooling is a relatively common method of manufacturing for various industries, there are a number of additional benefits to using family tooling in DELMIAWORKS as opposed to other manufacturing ERP (Enterprise Resource Planning) systems.

Below we’ll explain what family tooling is and what benefits your business could gain by using family tooling within DELMIAWORKS.

What is family tooling?

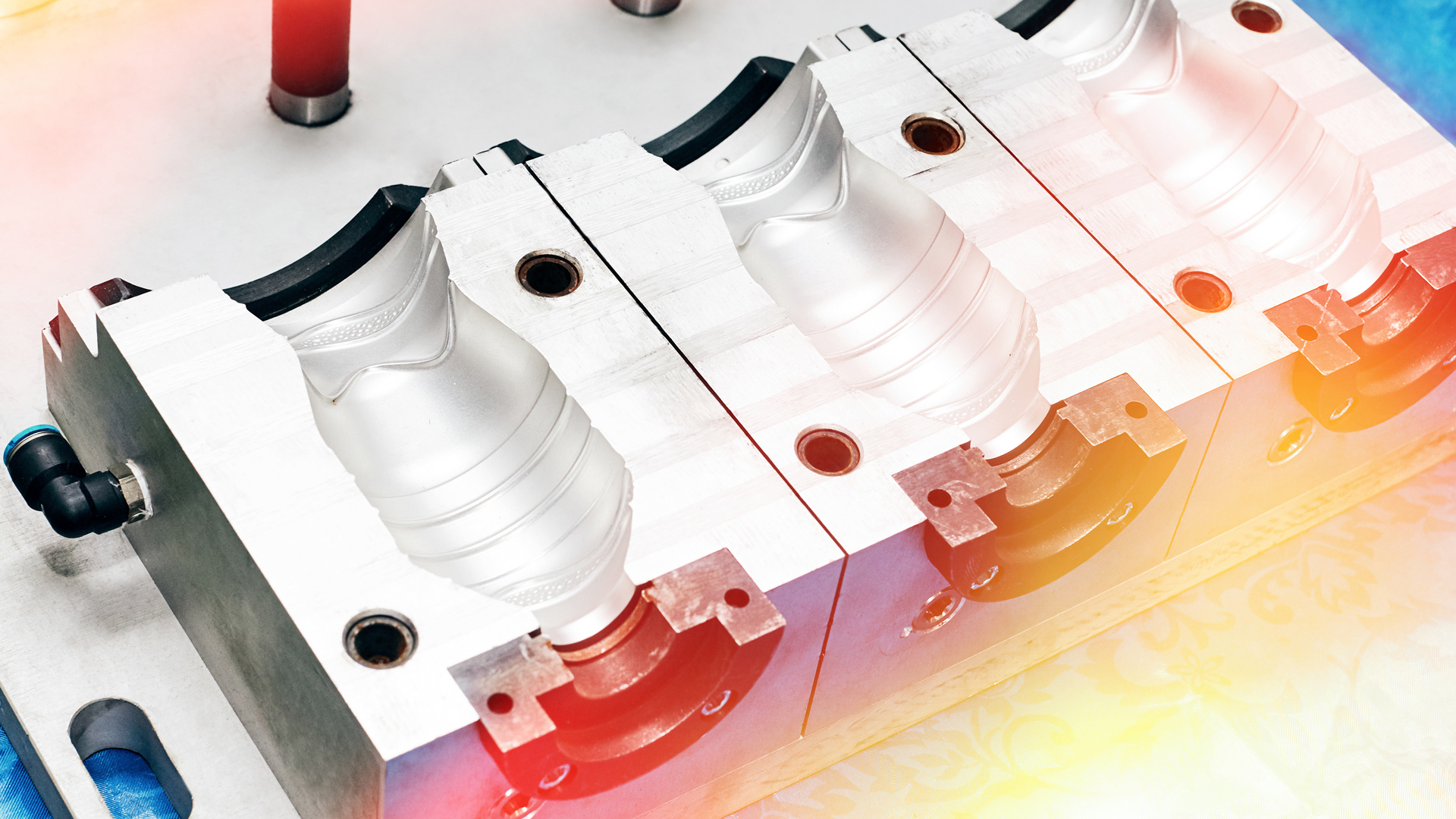

Family tooling is an efficient method of manufacturing, widely used within the injection moulding and metal stamping industries. Family tooling is a process by which you can make a number of different components from a single compression.

A family tool is the physical mould which is used in order to produce multiple components from one compression.

What are the benefits of family tooling within DELMIAWORKS?

As well as the standard benefits that family tooling can provide your business with, such as increased manufacturing productivity, reduced costs and increased profitability, there are a number of ways in which DELMIAWORKS really stands out from the crowd when it comes to family tooling.

In the majority of ERP systems, it’s very difficult to represent the exact family tooling process within the software.

Manufacturing ERP systems will generally have a process and as a result of that process there will be an output (production routing), which will create one part, product or component.

With the family tooling process, the key difference is that you will have multiple parts or components being made from a single cycle in that process.

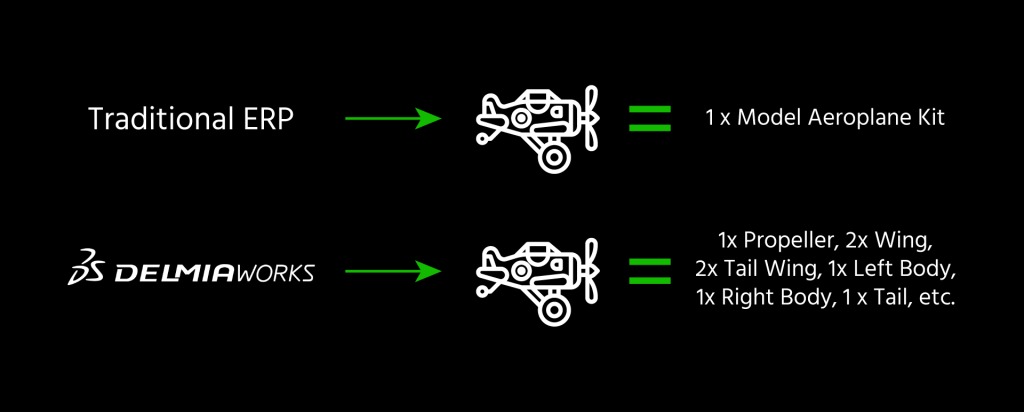

A traditional ERP system would represent all of the multiple components as one single component within the software.

Within DELMIAWORKS, it’s possible to more accurately represent this, with the system showing that this one process has actually created multiple different parts or components.

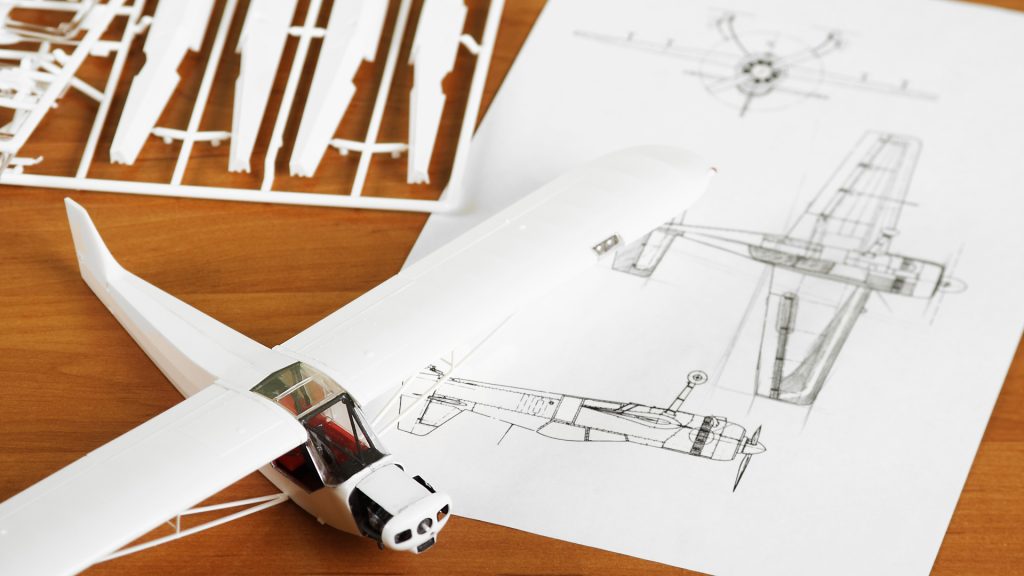

Let’s take, for example, a model aeroplane kit.

In the kit you will receive each of the parts required to build your model aeroplane. All the pieces are connected together in a plastic frame and all of these parts would be made from a single injection moulding compression.

Within DELMIAWORKS, we are able to create different part numbers for each component within that framework, for example the wings, the propellers and the tail.

With a more standard ERP system it would only be able to recognise the framework as the output, for example the entire frame for the model aeroplane, rather than each of the individual components contained within that frame.

True representation of shop floor activity

It’s only possible to accurately manage your business, and accurately plan your resources and time, if the software is capable of accurately reflecting the truth in your production process.

The majority of ERP systems aren’t capable of doing this because they only have one type of BOM (Bill of Materials) structure.

Within DELMIAWORKS there are 27 different BOM structures and family tooling is just one of those elements that it’s possible to facilitate.

Accurate resource and time allocation

With DELMIAWORKS being able to truly represent the activity that is taking place on your shop floor, it means that you’re able to much more accurately allocate time and resources to each and every component that you are producing as part of your manufacturing process.

This helps you prevent overcommitting time or resources to production and as a result, will help your business to be more productive and run more efficiently.

Learn why some of the most profitable and well run plastics processing plants use DELMIAWORKS.

Calculate and spread costs across individual components

Being able to break down the components of a family tool within the software is exactly how DELMIAWORKS makes it possible for you to calculate and spread the costs of a job against each of the components.

Rather than just being able to see how much it costs to make one final product, you’re able to see exactly how much it costs to make each one of the components contained within it, based on the material requirements of each component you’re creating within the family tool.

Access to this level of granular information about your manufacturing process makes it incredibly easy for executives to make informed business decisions, as they have full visibility of the truth within the production process.

Family tooling can be an especially useful method of producing components and our team here at Proximity are experts in implementing family tooling for businesses within the DELMIAWORKS manufacturing ERP.

DELMIAWORKS helps you meet the challenges of fluctuating raw material costs; multi and family tooling needs; regrind and consumption tracking and management, and shelf life management to achieve greater profitability.

Would you like to find out more about how DELMIAWORKS can improve the efficiency and profitability of your business?

FIND OUT NOW >

Posted by Rob on 11th March 2021.